Selecting the right printing machine is crucial for businesses that want to optimize productivity, improve print quality, and reduce operational costs. At Meditek Printing Solutions, our approach to understanding a client’s needs goes beyond simply selling a machine, we focus on delivering advanced printing solutions that align perfectly with the client’s production goals, materials, and budget.

Here’s a step-by-step look at how the Meditek team analyzes client requirements and recommends the ideal printing machine:

1. Understanding the Client’s Business and Industry

The first step is gaining a clear understanding of the client’s business operations, industry requirements, and production processes. Meditek’s team evaluates:

- Industry type: FMCG, packaging, electronics, automotive, medical, or promotional products.

- Production volume: Small, medium, or large-scale operations.

- Type of products: Bottles, containers, electronics components, promotional items, or industrial parts.

- Branding or regulatory requirements: Whether the client needs high-quality visual labels, compliance markings, or durability against wear, moisture, or chemicals

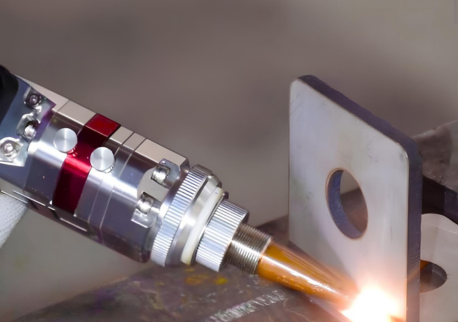

This foundational understanding helps our team identify the specific type of printing machine — whether it’s a multi-colour pad printing machine, laser marking machine, or digital label printer.

2. Analyzing Material and Printing Surfaces

Every client works with different materials and surfaces, which directly impacts the choice of printing technology. Meditek evaluates:

- Surface types: Paper, BOPP, polyester, glass, metal, plastic, or PVC.

- Surface texture: Smooth, rough, curved, irregular, or embossed.

- Colour requirements: Single colour, multi-colour, or photographic-quality prints.

- Durability needs: Resistance to friction, moisture, chemicals, or UV exposure.

By understanding these factors, Meditek ensures the recommended machine can produce high-quality, long-lasting prints on the client’s specific products.

3. Evaluating Production Capacity and Speed Requirements

Printing needs vary depending on the client’s production volume. Meditek analyzes:

- Daily or monthly production targets.

- Batch sizes and frequency of changeovers.

- Speed requirements for high-volume runs versus short customized runs.

This step ensures the client receives a printing solution that meets output expectations without causing downtime or overburdening operators.

4. Considering Customization and Automation Needs

Clients often require printing machines that can handle customization, variable data, or multi-version printing. Meditek examines:

- Need for multi-colour printing or high-resolution designs.

- Integration with existing production lines or ERP systems.

- Semi-automatic or fully automatic workflows to improve efficiency.

- Ease of operation and training requirements for staff.

By analyzing these factors, Meditek recommends machines that enhance productivity while simplifying operations.

5. Assessing Budget and ROI

Meditek believes in providing solutions that deliver long-term value. Our team evaluates:

- budget and investment capability

- Cost per print or per unit production

- Maintenance, consumables, and energy efficiency

- Expected return on investment (ROI)

This ensures the client gets the best combination of performance, quality, and affordability.

6. Presenting the Ideal Solution

After completing a thorough analysis, Meditek presents a tailored recommendation, including:

- Recommended machine model (pad printing, laser marking, or digital label printer)

- Technical specifications suitable for the client’s production needs

- Optional add-ons such as automation modules, multi-colour printing, or software integration

- Demonstrations or sample prints to validate quality and performance

This approach builds confidence in the client and ensures they choose the printing machine that truly meets their needs.

7. Continuous Support and Follow-Up

Choosing the right machine is just the beginning. Meditek provides ongoing support to ensure seamless implementation:

- Installation and calibration

- Staff training and operational guidance

- Regular maintenance and service support

- Assistance in scaling production or upgrading machines as requirements grow

This end-to-end service ensures the client maximizes the benefits of their Meditek printing solution.

Conclusion

At Meditek Printing Solutions, the focus is on understanding what the client truly needs rather than offering a generic product. By analyzing industry requirements, materials, production volume, automation needs, and budget, Meditek recommends the right printing machine that enhances productivity, ensures high-quality output, and delivers long-term value. Looking for the perfect printing solution for your business? Contact Meditek Printing Solutions today, and let our experts recommend the ideal machine tailored to your requirements!