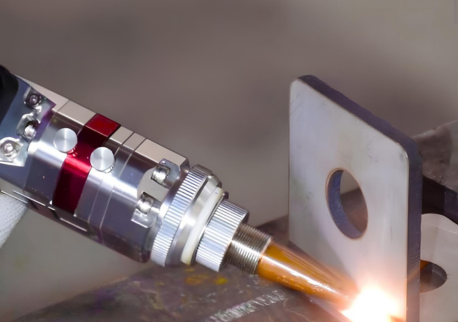

Industrial laser printing machines are powerful tools for modern production industries. Unlike consumer printers, these machines are built to handle high-volume printing, marking, and coding tasks across manufacturing units, from automotive parts and electronics to packaging and promotional products. Industrial laser printing machines use a focused laser beam to produce sharp, precise, and permanent prints quickly and efficiently.

Because they operate continuously and under demanding conditions, businesses often ask: Do industrial laser printing machines need maintenance? The short answer is yes, even though they are designed for durability and minimal downtime, regular maintenance ensures long-term performance, consistent quality, and lower operating costs.

1. Why Maintenance Matters for Industrial Laser Printers

Industrial laser printing machines are built to be robust and reliable, and they typically require less frequent maintenance than traditional ink-based industrial printers. However, they still have moving parts, optical components, and cooling systems that benefit from routine checks.

1.1 Preventing Downtime

Regular maintenance prevents small issues from becoming major production stoppages. A clean machine runs smoothly, keeps production lines moving, and ensures output remains accurate.

1.2 Consistent High-Quality Output

Dust, debris, or misalignment in any part of a laser system can affect print precision. Routine care helps ensure every printed label, barcode, or mark stays crisp and readable.

1.3 Long-Term Reliability

Even the most durable machine components can wear over time. Regular inspection and service extend the life of critical parts such as optics, lenses, and mechanical assemblies, resulting in lower maintenance and replacement costs.

2. What maintenance does a laser printer need?

Industrial laser printers may not need daily upkeep like consumer devices, but they do require scheduled care:

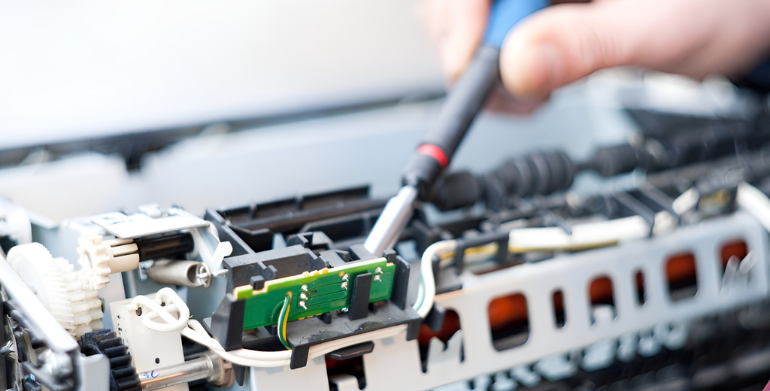

2.1 Cleaning Optical Surfaces

To ensure beam quality, the laser's optical path, which includes lenses and mirrors, must be kept clean. Regular cleaning reduces energy loss and maintains excellent print accuracy.

2.2 Cooling System Checks

These machines generate heat while in continuous operation. Maintaining airflow, cleaning filters, and checking coolant levels in air-cooled or water-cooled systems enables consistent temperature management and prevents overheating.

2.3 Mechanical and Structural Inspection

Vibration, dust, and wear can all cause components to loosen over time. Mechanical structures, fasteners, and motion systems benefit from periodic examination to maintain alignment and precision.

2.4 Environmental Control

Clean workstations and sufficient ventilation limit the likelihood of tiny particles accessing critical regions of the machine, particularly in dusty industrial settings.

2.5 Professional Servicing

Even well-maintained devices benefit from an annual or semi-annual professional inspection. Trained technicians can verify laser power outputs, recalibrate components, and update software or firmware when necessary.

3. How Long Can Industrial Laser Printers Run Without Maintenance?

Well-made industrial laser printers are built to last and can run for long periods of time with little intervention. However, avoiding maintenance permanently is not recommended. Even systems described as "minimal maintenance" require annual inspections, particularly in situations with extensive use or high dust levels.

3.1 Is it worth repairing a laser printer?

Absolutely. For businesses that rely on these machines for daily production:

- Maintenance safeguards output quality

- Reduces unexpected downtime

- Maximizes return on investment

- Lowers overall operating costs

Even though industrial laser printers are more resilient than consumer models, neglecting maintenance can shorten lifespan, compromise quality, and increase long-term costs.

Final Thoughts

Industrial laser printing machines are remarkable for their speed, precision, and efficiency in business environments. While they require less maintenance than older or ink-dependent systems, regular care remains essential. With routine cleaning, cooling system checks, structural inspections, and professional servicing, industrial laser printers can deliver reliable performance, sharp prints, and production confidence for years.

Visit Meditek Printing Solutions to get a quote, explore customized solutions, and connect with us to choose the right machine for your business needs.